Garden sculpture "Aphrodite small", bronze

Garden sculpture "Aphrodite small", bronze

Quick info

limited, 99 copies | numbered | signed | bronze | chiselled | patinated | size 32 x 20 x 25 cm (h/w/d) | weight approx. 6.2 kg

Detailed description

Garden sculpture "Aphrodite small", bronze

The name of the goddess of love and beauty translates as "the foam-born", for, in Greek mythology, she emerges from the water. The blue patina on Bodirsky's Aphrodite refers to this, regardless of whether she finds her place in the garden pond or on solid ground.

Edition in bronze, cast using the Lost-Wax-Process, chiselled and patinated by hand. Limited edition of 99 copies, numbered and signed. Size 32 x 20 x 25 cm (h/w/d). Weight approx. 6.2 kg.

Customer reviews

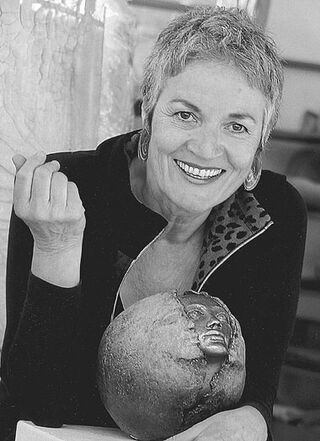

About Maria-Luise Bodirsky

Born in 1952, sculptor and ceramist

It is the basic elements of earth, water, fire and air that the sculptor and ceramist Maria-Luise Bodirsky, born in 1952, combines in her sculptures and the working process. Clay is her elementary artistic medium when capturing, tracing and depicting the inner and outer conditions of her figures.

Bodirsky draws inspiration for her archaic-looking figures from the early human history such as ancient Egyptian culture, Greek mythology and the Old Testament, or modern literature for example of Pablo Neruda.

An alloy of copper with other metals (especially with tin) used since ancient times.

When casting bronze, the artist usually applies the lost-wax technique which is dating back more than 5000 years. It's the best, but also the most complex method of producing sculptures.

First, the artist forms a model of his sculpture. It is embedded in a liquid silicone rubber mass. Once the material has solidified, the model is cut out. The liquid wax is poured into the negative mould. After cooling down, the wax cast is removed from the mould, provided with sprues and dipped into ceramic mass. The ceramic mass is hardened in a kiln, whereby the wax flows out (lost mould).

Now we finally have the negative form, into which the 1400° C hot molten bronze is poured. After the bronze had cooled down, the ceramic shell is broken off and the sculpture is revealed.

Now the sprues are removed, the surfaces are polished, patinated and numbered by the artist himself or, to his specifications, by a specialist. Thus, each casting becomes an original work.

For lower-quality bronze castings, the sand casting method is often used which, however, does not achieve the results of a more complex lost-wax technique in terms of surface characteristics and quality.

Term for an art object (sculpture, installation), which is produced in multiple copies in a limited and numbered edition according to the artist‘s will.

Artist's multiples have been called the most accessible and affordable art on the market.

A plastic work of sculptural art made of wood, stone, ivory, bronze or other metals.

While sculptures from wood, ivory or stone are made directly from the block of material, in bronze casting a working model is prepared at first. Usually, it is made of clay or other easily mouldable materials.

The prime time of sculpture after the Greek and Roman antiquity was the Renaissance. Impressionism gave a new impulse to the sculptural arts. Contemporary artists such as Jorg Immendorf, Andora, and Markus Lupertz also enriched sculptures with outstanding works.